All of Turbonetics’ high performance wastegates and valves are designed and tested to control boost and flow large volumes of exhaust gases. Turbonetics' wastegates feature investment cast stainless steel bases, precision machined parts, high temperature resistant diaphragms, computer modeled and flow tested inconel valve designs and v-band connections. These wastegates perform under pressure and handle high EGTs (Exhaust Gas Temperatures) to protect your engine from over boosting while efficiently evacuating hot gases to lower back pressure when running under wide open throttle.

All of Turbonetics’ high performance wastegates and valves are designed and tested to control boost and flow large volumes of exhaust gases. Turbonetics' wastegates feature investment cast stainless steel bases, precision machined parts, high temperature resistant diaphragms, computer modeled and flow tested inconel valve designs and v-band connections. These wastegates perform under pressure and handle high EGTs (Exhaust Gas Temperatures) to protect your engine from over boosting while efficiently evacuating hot gases to lower back pressure when running under wide open throttle.

All of our by-pass valves are engineered to efficiently alleviate boost pressure contained within the induction system by venting or re-routing air pressure to prevent surging and unnecessary wear on the turbocharger. Our wastegate and by-pass valve lineup is able to be applied on low displacement (< 1 liter), low boost (< 5 psi) applications all the way up to large 10+ liter engines running 100+ psi in compound boost setups.

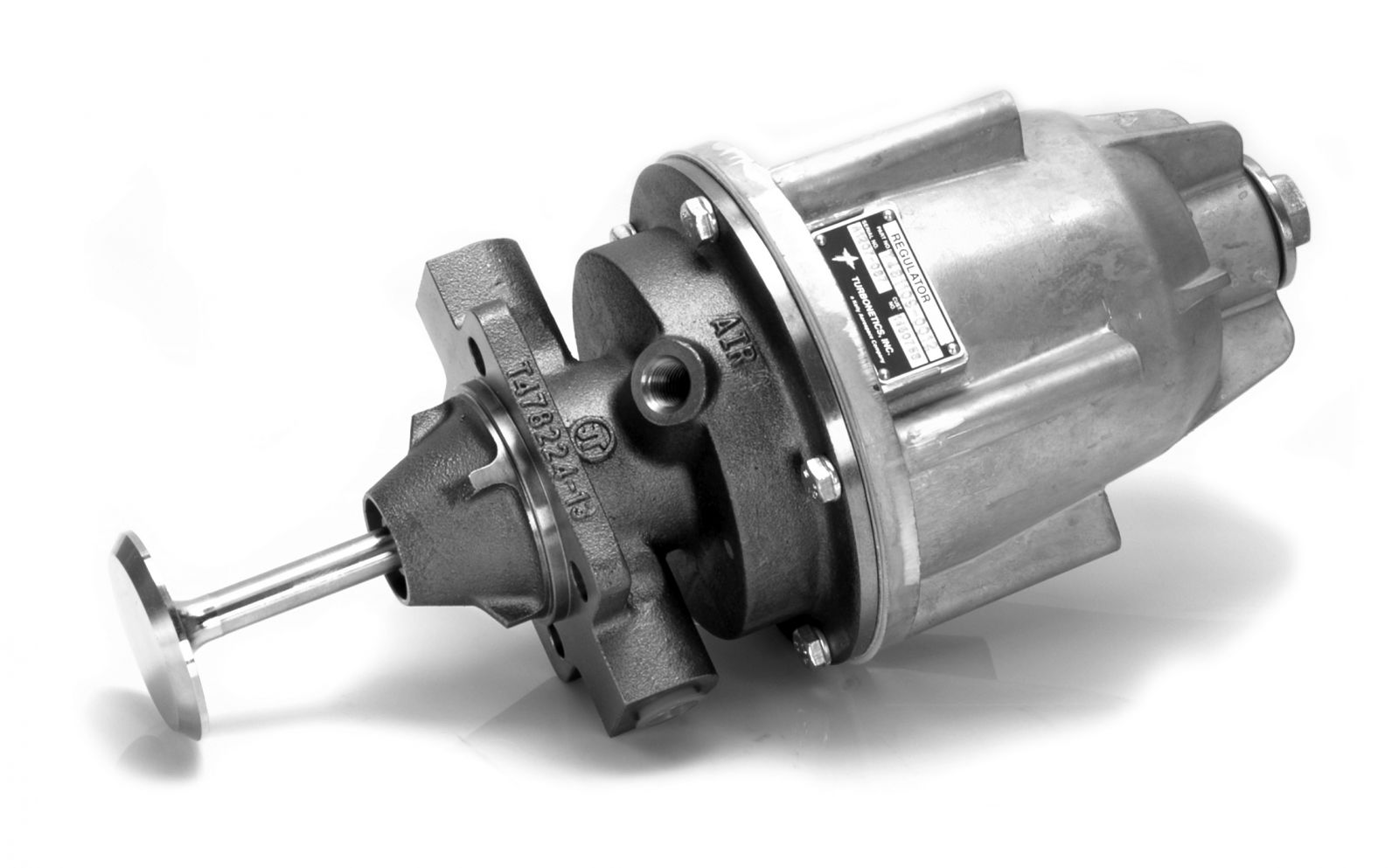

From automotive gasoline to natural gas powered stationary engines, Turbonetics has your boost control needs covered. Turbonetics industrial products are built to last. Offered as original equipment on large displacement natural gas and diesel power plants, our regulators endure extreme hours and conditions to control boost year after year. Made in a variety of different configurations for numerous types of industrial applications, these valves use the latest technology and materials specs to deliver on strict OEM requirements.

• Multiple configurations available for a wide variety of engine types and sizes, including diesel and natural gas

• Computer aided designs allow maximum flow and precise boost control

• Patented valve designs aid in reducing backpressure to optimize horsepower capabilities

• High strength components allow extreme use and long life